COOLING & CONDENSER COIL MACHINERY

Elevating our manufacturing capabilities to new heights, we have invested in state-of-the-art machinery designed for cutting-edge cooling and condenser coil production. Our extra modern equipment encompasses precision-engineered machinery and innovative technologies that redefine industry standards. With automated processes and smart automation, we ensure efficient and reliable production, delivering superior quality coils with unmatched precision.

Our commitment to excellence drives us to continuously optimize our manufacturing capabilities, offering tailor-made solutions to meet the diverse needs of our clients. From energy-efficient cooling systems to customizable production lines, our machinery stands at the forefront of innovation, empowering us to deliver the highest quality products to our valued customers.

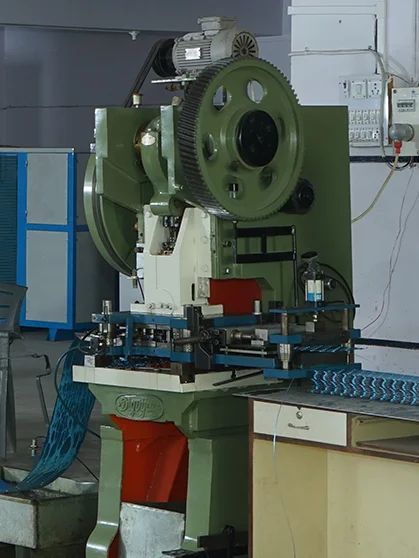

Fabrication Machine

At SBC Cooling Pvt. Ltd., we pride ourselves on utilizing cutting-edge fabrication machinery to ensure the highest quality products for our customers. our fabrication equipment is meticulously maintained and operated by skilled technicians, guaranteeing precision and accuracy in every component we produce. From our air-cooled chillers to our water-cooled chillers, each unit undergoes a rigorous fabrication process, where attention to detail is paramount.

With our top-of-the-line machinery, we can confidently deliver products that exceed industry standards in performance, durability, and reliability. Trust SBC Cooling Pvt. Ltd. for superior quality cooling solutions crafted with precision and expertise.

Puf panel making machine

Our high-performance puff panel making machine is Designed with precision engineering and advanced technology, our puff panel making machine ensures the production of superior-quality insulated panels for a wide range of applications.

Key Features:

-

High Efficiency: Our puff panel making machine is equipped with advanced automation features, resulting in high production efficiency and consistent product quality.

-

Versatility: With customizable settings and configurations, our machine can produce a variety of puff panels tailored to meet specific project requirements, including varying thicknesses, sizes, and insulation materials.

-

Accuracy: Each panel produced by our machine undergoes strict quality control measures to ensure precise dimensions, uniform density, and excellent thermal insulation properties.

-

Energy Efficiency: Designed with energy-saving features, our machine optimizes resource utilization and minimizes waste, contributing to sustainable manufacturing practices.

-

Reliability: Backed by our team of experienced technicians and comprehensive maintenance protocols, our puff panel making machine operates reliably and consistently, ensuring uninterrupted production and on-time delivery.

-

Customization: Our flexible manufacturing capabilities allow us to accommodate custom orders and unique specifications, providing tailored solutions to meet diverse project requirements.

Laser Cutting Machine

Our commitment to excellence shines through every cut, delivering unmatched quality and precision in every project.

Innovative Features:

-

Precision Redefined: Our advanced laser cutting technology utilizes the latest in laser technology to redefine precision, achieving intricate cuts with micron-level accuracy, ensuring flawless results every time.

-

Efficiency Unleashed: Powered by high-speed capabilities, our laser cutting technology enables swift and efficient processing of a diverse range of materials, optimizing productivity without compromising on quality.

-

Versatility Unmatched: From metals to plastics and beyond, our laser cutting technology offers unmatched versatility, seamlessly adapting to the unique requirements of each project with ease and precision.

-

Automation Excellence: Harnessing the power of automation and cutting-edge software integration, our technology-driven approach minimizes human error and maximizes workflow efficiency, ensuring consistent, high-quality results with every cut.

-

Quality Assurance: At every step of the process, our laser cutting technology undergoes rigorous quality control measures, ensuring that each cut meets the highest standards of precision, consistency, and excellence.

-

Innovation at the Core: We are committed to pushing the boundaries of innovation, continuously investing in cutting-edge technology to deliver solutions that exceed expectations and set new standards of excellence.

-

Expertise and Dedication: With a team of skilled technicians and engineers dedicated to their craft, we bring years of expertise and a passion for perfection to every project, ensuring unparalleled results that speak for themselves.

-

Premier Production Facility: Situated within our state-of-the-art production facility, our laser cutting technology operates in a meticulously controlled environment optimized for precision and efficiency, guaranteeing superior quality and consistency in every cut.

Cnc - Bending & Shearing Machine

Discover the pinnacle of precision engineering with our state-of-the-art CNC Bending & Shearing Machine, a cornerstone of our advanced production facilities. Featuring cutting-edge servo-controlled hydraulic systems and CNC technology, our machine offers unparalleled accuracy and repeatability in bending and shearing operations. With multi-axis control and automatic tool change capabilities, it can effortlessly handle a wide range of materials, including stainless steel, aluminum, and mild steel, with thicknesses up to [insert thickness range]. Equipped with intelligent software for real-time monitoring and optimization of bending parameters, our machine ensures optimal performance and efficiency while minimizing material waste.

Its high-speed operation, combined with advanced safety features such as light curtains and interlocking systems, guarantees smooth and secure production processes. Backed by our team of skilled technicians and engineers, we provide comprehensive training and support to maximize the potential of our CNC Bending & Shearing Machine, delivering precision-engineered components that exceed industry standards and customer expectations.